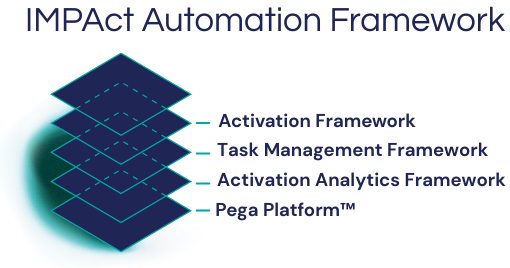

IMPAct Automation Framework

Automated Activations for enhanced operational efficiency

Streamline Maintenance Planning and Scheduling

The maintenance and sustainment of strategic assets, including ships, aircraft, and satellites, is complex and requires detailed planning, execution, and tracking of critical inputs and tasks. The support organizations responsible for these operations often struggle with fragmented planning processes, manual coordination, and disconnected systems, resulting in operational inefficiencies, resource misallocation, and inability to proactively manage mission-critical maintenance activations.

The IMPAct (Integrated Maintenance Planning & Activation) Automation Framework streamlines the technology integration and adoption processes by modernizing complex operational workflows. Enabling personnel through activation milestones, task setting, determining maintenance capabilities, and improved stakeholder visibility throughout decision making processes.

Explore the IMPAct Automation Framework

The IMPAct Automation Framework supports government agencies' adoption of new technologies by enabling enterprise-scale maintenance planning, optimizing cost management, and enhancing operational efficiency. Our tool is adaptable and scalable to support your complex and dynamic enterprise.

Plan

Establish maintenance schedules and activation milestones with automated workflow assignments

Execute

Monitor real-time progress and manage workforce allocation

Analyze

Review performance dashboards and access comprehensive reporting on maintenance cycles

Optimize

Address operational gaps and continuously refine processes based on predictive data insights

IMPAct Automation Framework Features

- Intelligent Automation — AI-powered decisioning, predictive analytics and workflow automation strengthen decision-making and resource allocation.

- Enhanced Operational Efficiency — Reduced maintenance cycle times through streamlined workflows, reduced manual intervention, and elimination of process bottlenecks.

- Optimized Cost Management — Reduced maintenance costs achieved through improved labor utilization, reduced waste, and better visibility into cost drivers.

- Improved Readiness — Improved speed of return of critical assets to operational status, increased reliability and availability of maintained equipment, and better support for deployment requirements.

Our Pega Services

srcLogic has a robust team of Pega Certified Consultants to guide you through your Pega journey. Discover how our solutions can get your Pega applications to do the most for your business.